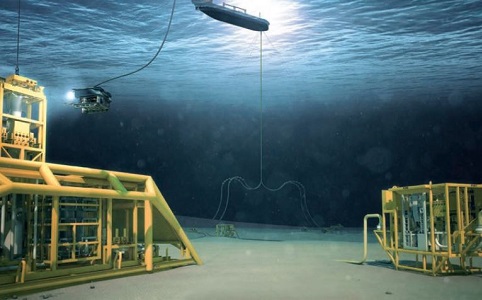

Subsea Linux based MCS

Working on behalf of OneSubsea (formally Cameron), a subsea Oil & Gas production equipment manufacturer in Celle Germany, developing Subsea Linux based MCS (Master Control Station) and IWOCS equipment to monitor and control subsea production wells and manifolds.

Projects included JSM and TVEX for Chevron in the Gulf of Mexico, Rosebank and Captain for Chevron in the North Sea, White Rose and North Amethyst for Husky Energy off Newfoundland, and Global 10K and Global MUX for Petrobras in Brazil.

Deliverables included SDS, FDS, FAT and IOM document development, equipment protection interlocking, shutdown sequencing, simulation and Modbus/OPC based interfaces to the production control systems on the customer FPSOs, platforms or onshore production facilities. Also developed a PLC based MCS using Allen Bradley redundant ControlLogix PLCs with both an iFix and InTouch front-end.

Subsea PLC Based MCS

Working on behalf of OneSubsea (formally Cameron), a Subsea Oil & Gas production equipment manufacturer in Houston Texas, developing Subsea PLC based MCS (Master Control Station) equipment to monitor and control subsea production wells and manifolds.

Projects included Kizomba B for Exxon Mobil in Angola, Captain for Chevron in the North Sea and Ceiba for Hess in Equatorial Guinea.

Deliverables included SDS, FDS, FAT and IOM document development, equipment protection interlocking, shutdown sequencing, simulation and Modbus/OPC based interfaces to DeltaV and Honeywell DCS production control systems on the customer FPSOs, platforms or onshore production facilities. Programmed redundant GE Fanuc 90-70 PLCs which interfaced with subsea via onboard VME computers running a propriety protocol. Interfaced with topside Siemens S7 PLC based skid units via SST Profibus VME interface cards. Developed the redundant server based Cimplicity HMI with redundant Ethernet cabling.

Also developed various Linux based MCS projects for their facility in Celle Germany, which is OneSubsea’s main offering today.

Tank Farm – Oil & Gas

Designed and built a tank farm data acquisition system for BP refinery in Texas City, Texas. Based on redundant industrial Ethernet, the application utilised Allen Bradley CompactLogix PLCs as Modbus RTU masters interfacing to various tank gauges and MOV devices. The project included an OPC bridging application as a gateway to the plant’s Honeywell DCS.

Pharmaceuticals – DeltaV

Provided integration services at Schwarz Pharmaceutical (now UCB) in Shannon Co. Clare. Responsible for the design and testing of various CMs, EMs & Phases and responsible for faceplate/graphics standards and controller I/O configuration on Emerson’s DeltaV system.

Pharmaceuticals – PLC/SCADA

Provided integration services at Wyeth Medica in Newbridge. Design and build of new Contained Waste and Purified Water Distribution systems utilising Allen Bradley’s ControlLogix PLCs and iFix SCADA. Created ControlLogix PLI code for iBatch/PLC interfacing and developed ControlNet interfacing strategy for inter system PLC communications.

Pharmaceuticals – Freeze Dryers

Provided integration services at BOC Edwards in Buffalo, New York. Developed PLC/SCADA applications for Lyophilizes (Freeze Dryers) for European customers. The applications were 21CFR Part-11 compliant with SQL Server Alarm/Event/E-Signature archiving. Implemented and tested a iHistorian server and associated iFix SCADA collectors and the configuration of Proficy Portal. Implemented Domain based security and security synchronisation between a domain and iFix.

Glass Manufacturing

Assisted Millennium Control Systems Inc on large ControlLogix / iFix project in Durant, Oklahoma involving over twenty ControlLogix processors, over two hundred Allen Bradley PowerFlex drives and a distributed iFix architecture involving six redundant SCADA pairs and over thirty iFix clients. Performed drive setup and tuning, ControlLogix programming, iFix OPC driver configuration, automatic iFix database & TGD file creation and picture development.

Cement Manufacturing

Designed, developed and commissioned the control system for two Cemex owned cement manufacturing plants in the US. The systems were based on distributed Allen Bradley PLCs and a redundant iFix SCADA architecture. Developed PICS software based PLC I/O simulation to simulate the entire plant behaviour prior to onsite commissioning. Developed a tool to populate the PLC, SCADA and simulation databases and much of the PLC logic. Used same tool to populate motor schematics and loop sheets. In parallel I developed the company’s corporate automation standards.

Burner Management Systems

Designed, developed and commissioned Burner Management Systems on multiple furnaces for BP Chemicals in Pasadena Texas. The systems were based on ControlLogix PLCs in conjunction with Honeywell PlantScape.